🔄 Inventory Rotation

The Inventory Rotation module provides a comprehensive reporting and analysis tool for restocking operations between locations. It helps you analyze sales patterns at destination locations and available stock at central warehouses to make informed transfer decisions.

Before You Start: Make sure the system is configured according to the Setup Guide.

Why Use Inventory Rotation?

Save time - instead of manually checking sales and inventory levels, you get all the data in one place.

Make better decisions - you see exactly what and how much was sold at each location, so you know what to restock.

Avoid shortages and overstock - replenish inventory based on actual demand, not guesses.

Overview

The Inventory Rotation Report calculates and displays:

- Sales statistics from destination locations for a specified period

- Current inventory levels at both central and destination locations

- Available stock at the central location

- Suggested quantities for transfer orders in base or transfer units of measure

Key Features

- 📊 Sales Analysis - See what and how much sold during a selected period (e.g., last 30 days, current month)

- 📦 Inventory Levels - View stock at central and destination locations

- 🎯 Flexible Filters - Limit view to selected items, categories, or variants

- 📝 Quick Orders - Specify quantities and create a transfer order with one click

- ⚠️ Validation - System warns about problems (insufficient stock, incomplete packages)

How It Works

1. Open the Inventory Rotation Report

Navigate to the Inventory Rotation Report from the Reports and Analysis section in Business Central.

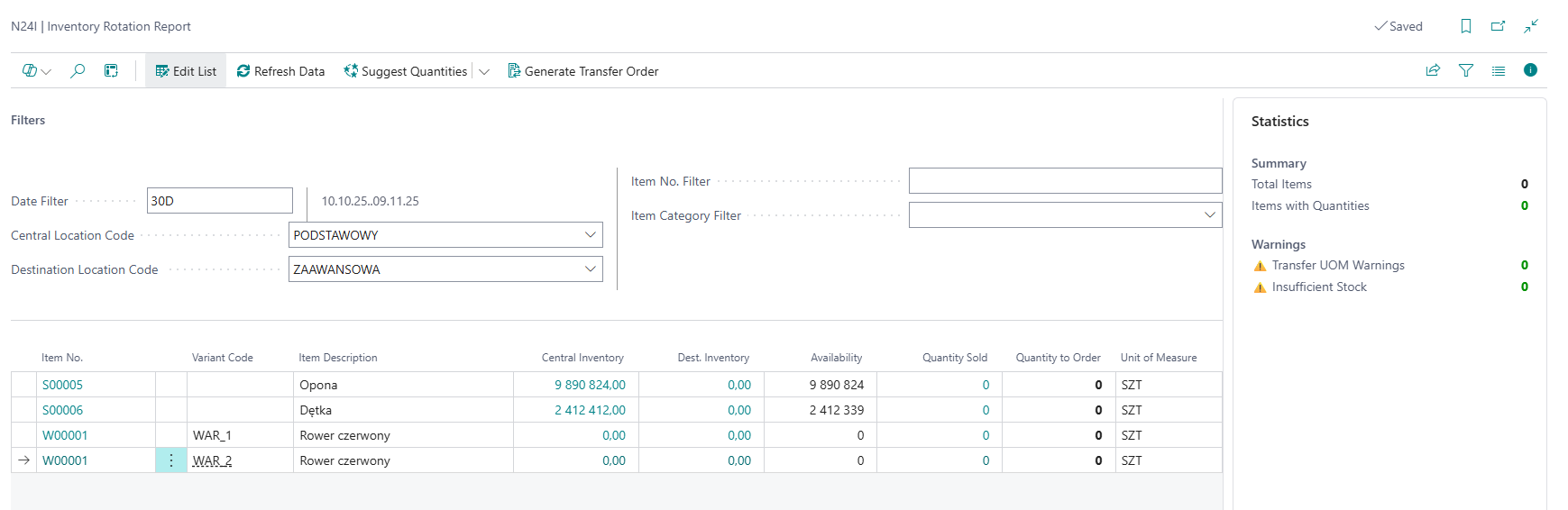

2. Configure Filters

The report requires you to set up filters before calculating data:

Required Filters

- Central Location Code - The warehouse where stock is available for transfer

Default value comes from configuration in Advanced Inventory Setup

- Destination Location Code - The location where items are sold and need restocking

- Date Filter - Period for sales calculation (e.g.,

30D,CM,1M,01/01/2024..01/31/2024)Default value:

30D(last 30 days) or value defined in Advanced Inventory Setup

Optional Filters

- Additional Item Filter - Limit analysis to specific items within the globally allowed items

You can click on the field to open filter builder and select items by number, type, or category

Global filter from Advanced Inventory Setup is always applied and cannot be removed by the user - this ensures only appropriate items are visible in the report

3. Load Data

Click the Load Data action to calculate inventory rotation statistics based on your filters. The system will:

- Find all items matching your criteria

- Calculate quantity sold at the destination location for the specified period

- Retrieve current inventory levels at both locations

- Calculate available stock at the central location

- Populate the report with all calculated data

4. Review the Results

Key columns in the report:

| Column | Description |

|---|---|

| Item No. / Description | Item number and name |

| Central Location Inventory | How much is in the main warehouse |

| Quantity Sold | How much sold in the selected period (click to see details) |

| Availability | How much you can transfer (includes open orders) |

| Qty. in Transfer UoM | Available quantity in transfer units (e.g., boxes, pallets) |

| Quantity to Order | Here you enter how much you want to transfer |

The report also contains additional columns: variants, destination location inventory, transfer units.

5. Specify Quantities to Order

You have several options to manage quantities:

Manual Entry

Enter the quantities you want to transfer in the Quantity to Order field. The system will automatically convert values between base units and transfer units.

Quick Actions for Quantities

- Suggest Quantities - Automatically fills Quantity to Order based on the difference between Quantity Sold and current Destination Inventory. Only affects items without existing quantities assigned.

- Round to Transfer UOM - Rounds down all Quantity to Order values to be evenly divisible by Transfer UOM, ensuring complete packages.

- Clear Quantities - Clears all assigned Quantity to Order values, allowing you to start fresh.

Note: If the quantity is not evenly divisible by the transfer unit, the line will be highlighted in red to indicate a warning.

6. Monitor Statistics

The Statistics FactBox on the right side shows:

- Total Items - Number of items in the report

- Items with Quantities - How many items have specified quantities to order

- ⚠️ Transfer UOM Warnings - Items with division problems by unit

- ⚠️ Insufficient Stock - Items that cannot be transferred (not enough stock)

7. Create Transfer Order

You have two options for creating transfer orders:

Generate Transfer Order (New)

Click the Generate Transfer Order action to create a new transfer order. The system will:

- Validate quantity divisibility by Transfer UOM

- Check that the transfer route is properly configured

- Create a new transfer order with all items that have Quantity to Order specified

- Clear all assigned quantities after successful creation

- Prompt you to open the newly created order

Add to Existing Transfer Order

Click the Add to Existing Transfer Order action to add lines to an existing open transfer order. The system will:

- Search for open transfer orders matching the same location combination (from Central to Destination)

- If no matching orders are found - ask if you want to create a new one instead

- If one matching order is found - automatically select it

- If multiple matching orders are found - display a list to choose from

- Confirm before adding lines to the selected order

- Add all items with Quantity to Order specified to the selected transfer order

- Clear all assigned quantities after successful addition

- Prompt you to open the updated order

Important: Transfer route must be previously configured in the system. Search in Business Central: Transfer Routes.

Note: Lines can only be added to transfer orders with Open status. Released orders cannot be modified.

Use Cases

Weekly Restocking - Set the date filter to last week (1W), select locations, and see what sold. Use this to restock stores.

Category Review - Filter by product category, see which items rotate quickly and require more frequent restocking.

Seasonal Preparation - Check sales from the same period last year and plan appropriate stock before the season.

Most Commonly Used Date Filters

The Date Filter field accepts standard Business Central date filter syntax:

| Filter | Description | Example Period |

|---|---|---|

30D |

Last 30 days | |

1M |

Last month | |

CM |

Current month | |

CW |

Current week | |

CY |

Current year | |

01/01/2025..01/31/2025 |

Specific date range |

Common Issues

"No items found"

- Check if filters are correct

- Make sure items meeting the criteria exist

"Transfer route not found"

- Search in Business Central: Transfer Routes

- Specify the in-transit location

Divisibility warning

- Adjust quantity to full packages

Insufficient stock

- Check incoming deliveries

- Reduce the quantity ordered

- Consider transferring from another location