Suggested Packages

Configuration

You can find instructions on how to configure this functionality here.

Information in Documents

Suggested packages can be calculated to optimize shipping for the following documents:

- Sales Order,

- Sales Quote,

- Warehouse Shipment,

- Posted Warehouse Shipment,

- Posted Sales Shipment,

- Posted Sales Invoice

Calculating Suggested Packages

Suggested packages are automatically calculated when entering and editing lines — primarily fields related to quantities and weights.

You can also manually trigger the calculation (e.g., after making changes to the Item Package Setup) by clicking the Calculate Packages action in the TMS tab.

If the packaging settings are incomplete or incorrect and you want to quickly correct them, you can go directly to the settings from the lines by clicking the Item Packages action in the TMS tab.

Previewing the Suggested Packages Effect

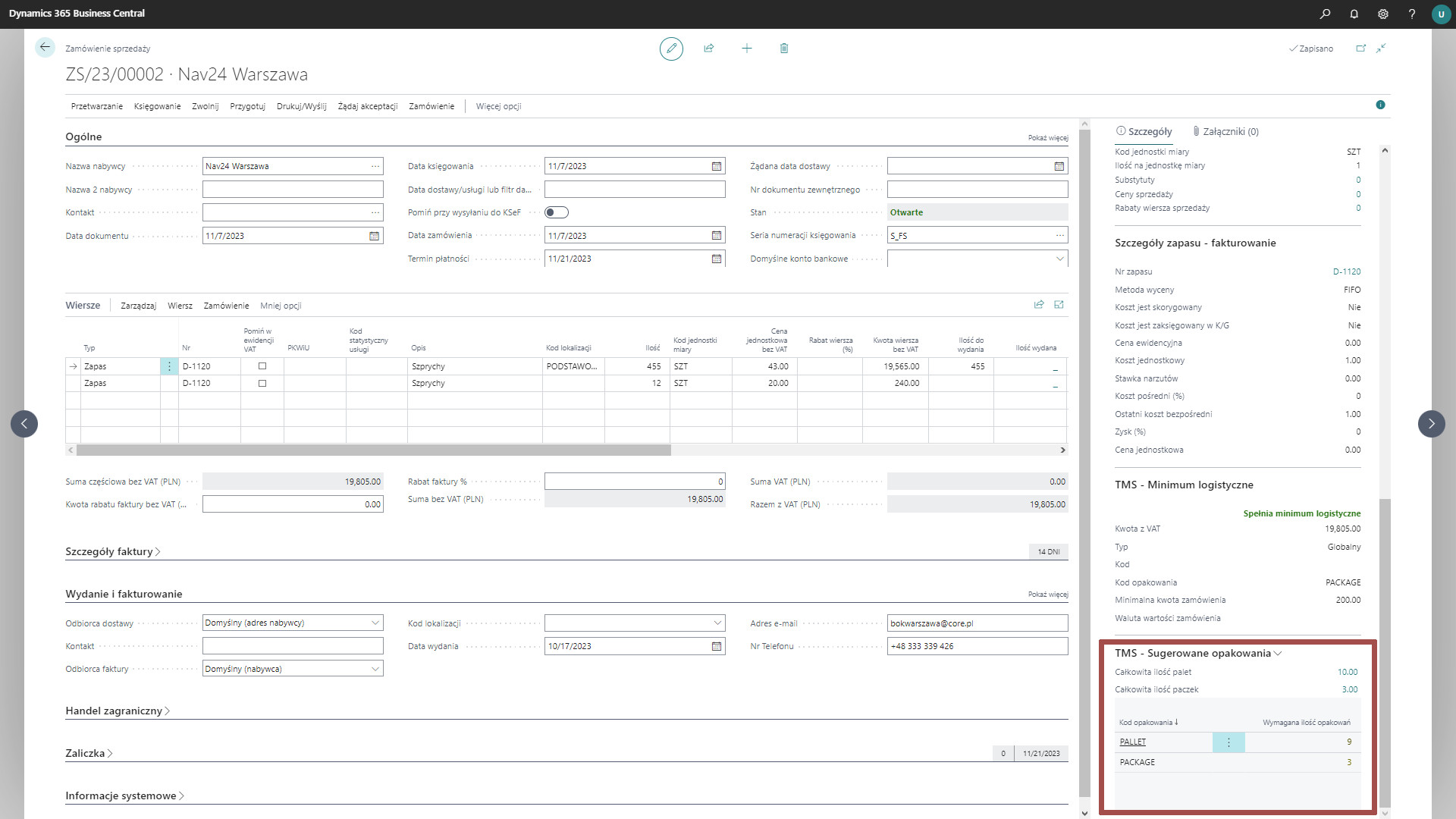

The results of the suggested packages calculation can be viewed in the FactBox pane on the right side of the document.

At the top of the TMS | Suggested Packages, we see a summary by packaging type: pallets and boxes.

Below, you can see the details of the calculations, such as:

- package code,

- total stock weight,

- suggested quantity of packages

Additional fields are also available, which can be customized through personalization.

The preview shows suggestions collectively for all lines in the document.

Adding a Package Line to the Order

If you want to sell/issue the packaging itself (e.g., a pallet), you can use the Add Packages as Lines action in the TMS tab.

The system will create a line for each package that has a defined Line Type, Code, and Price in the Packaging Settings, in a quantity corresponding to the suggested amount.

Calculation Method

Calculations are made based on the quantity and weight in the line, based on the defined thresholds in the Item Package Setup settings. The Settings allow you to select the packages into which we will pack a given stock or items from a specific item category. The settings clearly define the minimum and maximum weight and quantity that can be packed into one package.

Example

[Stock Line]: 6 pieces weighing a total of 6 kg

[Defined Setting]: One package holds 5 pieces of stock or 10 kg

The system calculates the required number of packages based on weight and quantity. The calculations indicate that it is more cost-effective to pack by weight, but the quantity limit imposes a restriction, so to correctly pack the items, 2 packages are needed. After all, we cannot fit 6 pieces of item into one package if it only holds 5.

The above package calculations are carried out for each line. Then, the same packages are summed by quantity.

The final step is to check if the calculated packages can be consolidated into one larger package, which is more economical for shipping. There is no point in sending 10 packages if they can be packed onto one pallet.

This is done using a special type in the Item Package Setup - For Package. When selecting a package, you can define the quantity and weight thresholds to pack these packages into a larger one.